Company Profile

Company Name : BANGKOK AI-TOA CO.LTD.

Industrial Estate 1/7 Moo2. Soi8. Rama2 Rd. Tambol Thasai, Amphur Muang Samutsakorn. Samutsakorn Province. Thailand 74000

TEL : 66-34-490-729-31 FAX : 66-34-490-727-28 Establishment : December 17,1990

Capital : BAHT 140,000.000- Exective : MR.SHINYA KIMURA/PRESIDENT

Number of employees : 650

Area of land : 38,500m2

Area of building : 25,000m2

Routine : Wire processing and Plastic(Resin)coating, Nickel-Chromium electroplating products, Electro polishing products, Part for air conditioner, Store fixture and Furniture, Shopping Cart, Part for home appliance, Part for automobile

Equipments and Products![]()

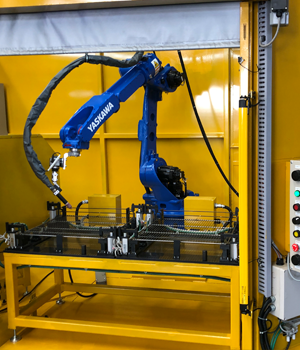

Robot Arc Welding

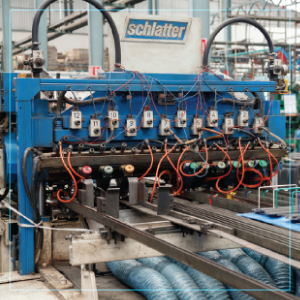

Automatic Mesh Welding Machine

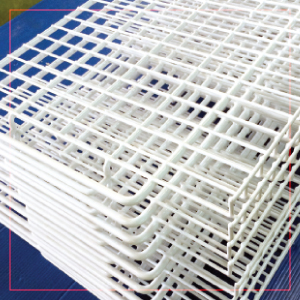

CNC Bending Machine

For various need! Flexible thinking to create the future!

We contribute to society taking advantage of various surface treatment technology, In order to make a customer's important goods more functional and more comfortable more beautifully.

Surface Treatment Equipments![]()

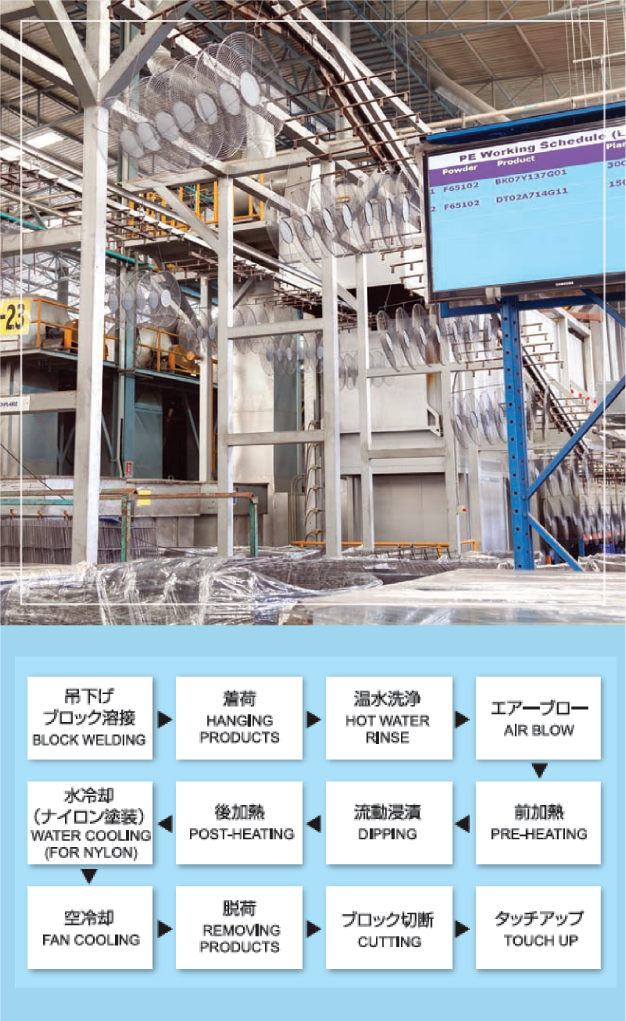

Fluidized Bed Coating

Thick coating layer are formed after washing the coating products, heated in furnace and then resin powder is fusion bonded by the heat of coating products when it is dipped in the fluid bedcontaining resin powder.

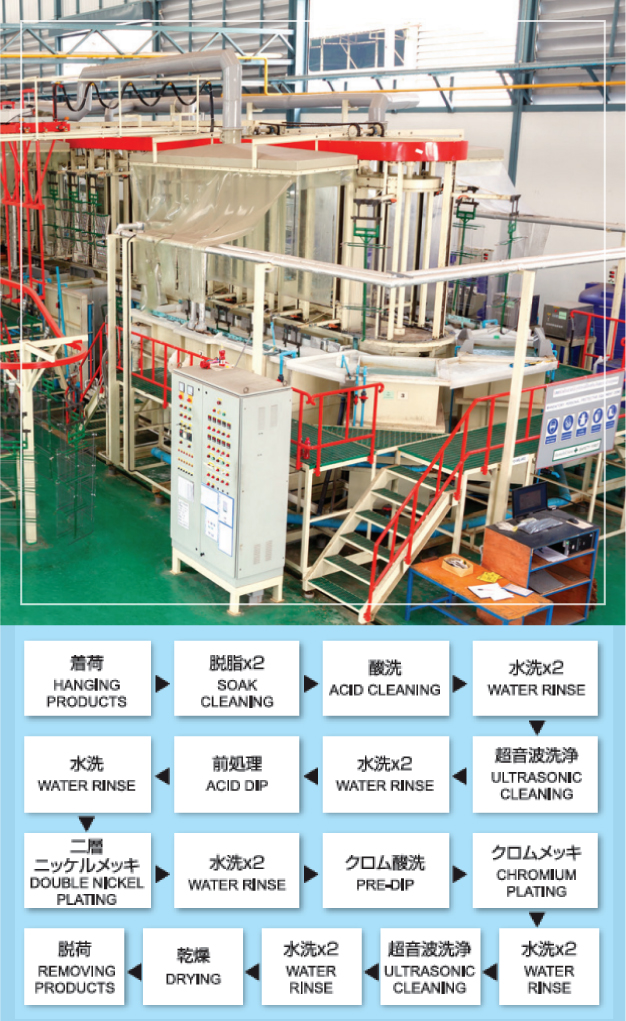

Nickel-Chromium plating

Decorative corrosion resistance plating surface is formed by removing ol by soak cleaning, acid cleaning and ultrasonic cleaning, making surface smooth (levelling) by Nickel deposit (Semi-bright nickel, bright nickel microporous nickel and then plating thin layer of chromium plating.

Electrostatic Power Coating

Smooth painted layer is formed by spraying the electric-charted resin powder by a electrostatic gun on the painting objects treated with zinc phosphating and then baked in the furnace.

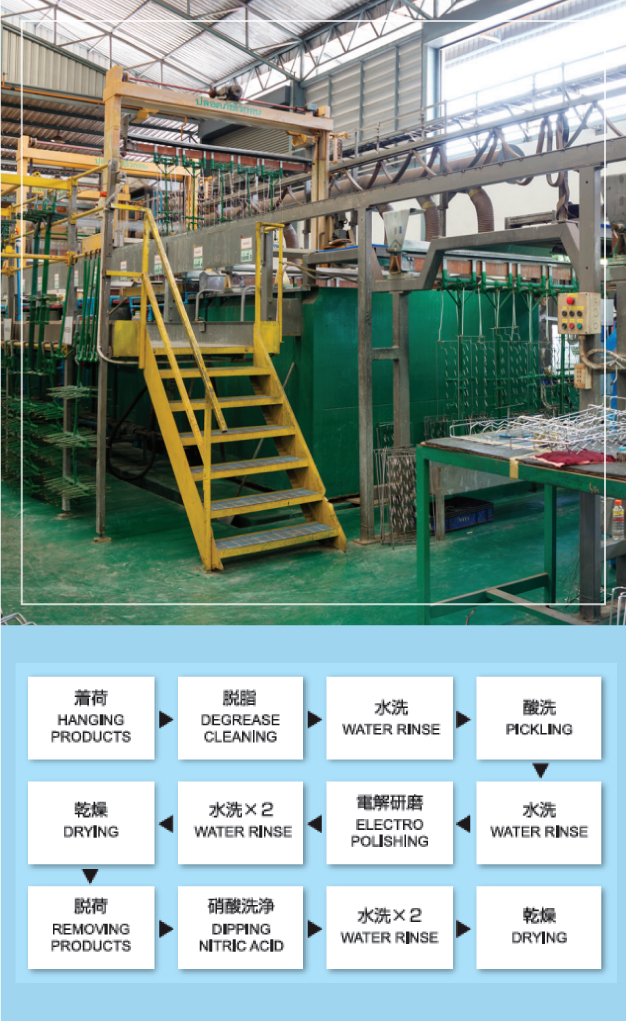

Electrolytic Polishing

Corrosion nesistance of stainless steel is improved by dipping the stainless steel in electrolyte, dissolving the stainless steel electrochemically, smoothed, polished and then applying passivation treatment.